Blog

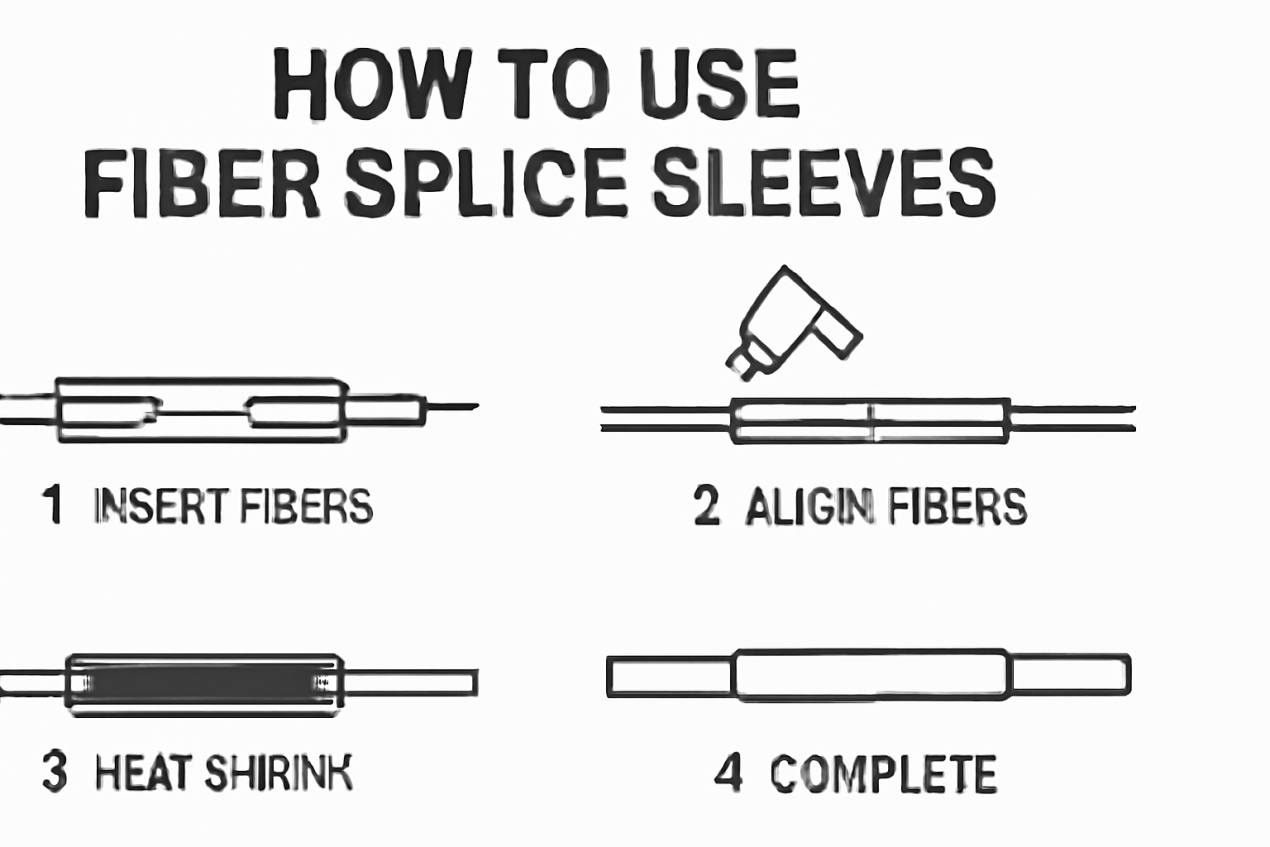

How to Use Fiber Splice Sleeves

Fiber Splice Sleeves are used in fiber optic splicing to protect bare fiber.

How to Use Fiber Splice Sleeves:

1. Preparation:

o Clean the fiber optic cable to ensure there is no dust or debris.

o Strip the cable carefully, exposing the fiber for splicing.

2. Splicing the Fiber:

o Align the fibers that need to be spliced, making sure the cores are perfectly matched.

o Use a fiber fusion splicer or mechanical splicing method, depending on the splice sleeve type.

3. Placing the Splice Sleeve:

o Slide the prepared splice sleeve over the spliced fibers. The sleeve should be centered over the spliced area, ensuring both ends of the fibers are inside the sleeve.

4. Heating the Sleeve (for Heat Shrink Sleeves):

o If using a heat-shrink splice sleeve, apply heat to the sleeve using a heat gun or oven. This will shrink the sleeve, securing the splice in place.

o Make sure the sleeve shrinks evenly to ensure a solid and reliable connection.

5. Cooling and Testing:

o Let the sleeve cool down before moving the cable to avoid damaging the splice.

o Test the fiber connection to ensure a strong signal.

RELATED NEWS

- Fiber Optic Attenuators – Precision Solutions for Signal Control 2023-03-20

- LC Fiber Optic Adapter: High-Quality Connectivity Solutions by Chengdu Focus Inf 2023-02-18

- SC Fiber Optic Adapter: High-Performance Connectivity Solutions by Chengdu Focus 2023-01-15

- Key Features of Fiber Optic Adapters 2023-04-05

- Difference Between Simplex and Duplex Fiber Optic Adapters 2023-02-22

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Yuki

Phone: +8618981876882

E-mail: yuki.hecy@cdfocusinfra.com

Whatsapp:+8618981876882

Add: No. 1760 century avenue, Chongzhou city, Sichuan province, China