Blog

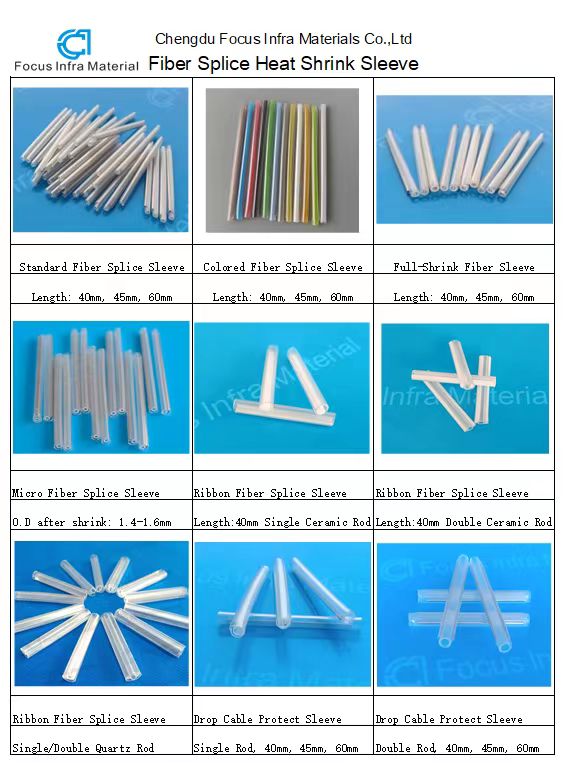

Different Types of Fiber Splice Sleeves

At Chengdu Focus Infra Materials Company, we offer a wide variety of fiber splice sleeves, each designed for specific fiber optic applications. Whether you're splicing single fibers, drop cables, microfibers, or ribbon cables, our splice sleeves provide the best in durability, protection, and reliability. Below, we introduce the key differences between our various fiber splice sleeves and their most common use cases.

1. Single Fiber Splice Sleeves

Overview:

Single Fiber Splice Sleeves are the most common type of splice sleeve used in fiber optic splicing, designed for protecting individual fiber splices.

Key Features:

Size: Designed for single optical fibers.

Material: Typically made from high-quality, heat-shrinkable polyolefin, offering excellent mechanical protection and environmental resistance.

Shrink Ratio: Usually a 2:1 shrink ratio to fit standard fiber sizes and provide a secure, tight-fitting seal.

Protection: Provides reliable protection against mechanical stress, moisture, and dust, ensuring long-lasting performance for the fiber splice.

Applications:

Telecommunications Networks: Used in standard telecom networks where single fiber connections are being spliced.

Data Centers and Fiber Networks: Ideal for splicing individual fibers in high-performance data center networks, offering enhanced signal integrity.

Field Maintenance and Installations: Commonly used in fieldwork for quick and easy fiber protection.

Why Choose This Model:

The Single Fiber Splice Sleeve is perfect for standard fiber optic installations, offering protection and security for individual fibers in a wide range of industries. Chengdu Focus Infra Materials company offers a wide size range of single fiber splice sleeves to meet market requirements.

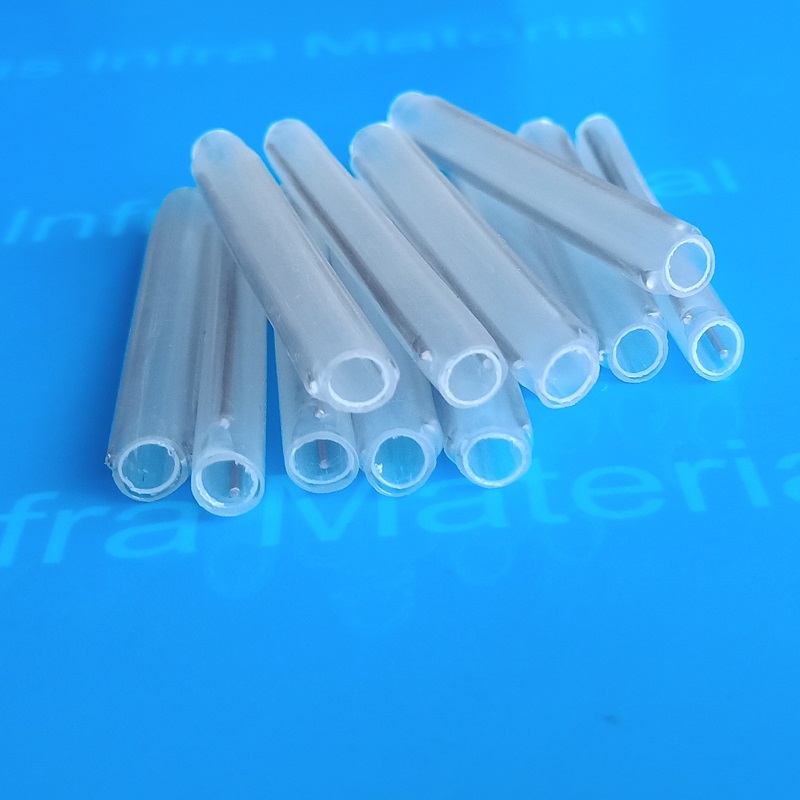

2. Drop Cable Fiber Splice Sleeves

Overview:

Drop Cable Fiber Splice Sleeves are specifically designed for splicing drop cables, which are typically used to connect homes or businesses to the main network. These sleeves provide additional protection due to the typically rugged environment drop cables face.

Key Features:

Size & Design: Designed to accommodate the larger diameter of drop cables and provide additional flexibility.

Durable Construction: Made from robust materials, often with a thicker, more durable shrink material compared to standard sleeves.

Shrink Ratio: Usually a 3:1 shrink ratio, enabling a secure fit over various drop cable sizes.

Enhanced Protection: Offers superior mechanical, environmental, and weather protection for outdoor and indoor drop cables.

Applications:

Fiber-to-the-Home (FTTH) Installations: Perfect for use in last-mile drop cable connections, providing protection for spliced fibers in outdoor and residential settings.

Outdoor Fiber Networks: Ensures the integrity and performance of spliced fibers in harsh environments, including urban and rural fiber networks.

Why Choose This Model:

The Drop Cable Fiber Splice Sleeve offers more durability and protection than standard sleeves, making it ideal for the more demanding environment of drop cable installations. Drop Cable Splice Sleeves produced by Chengdu Focus Infra Materials company with a large inner diameter so that you can put drop cable through the sleeves easily, which can help to improve your work efficiency.

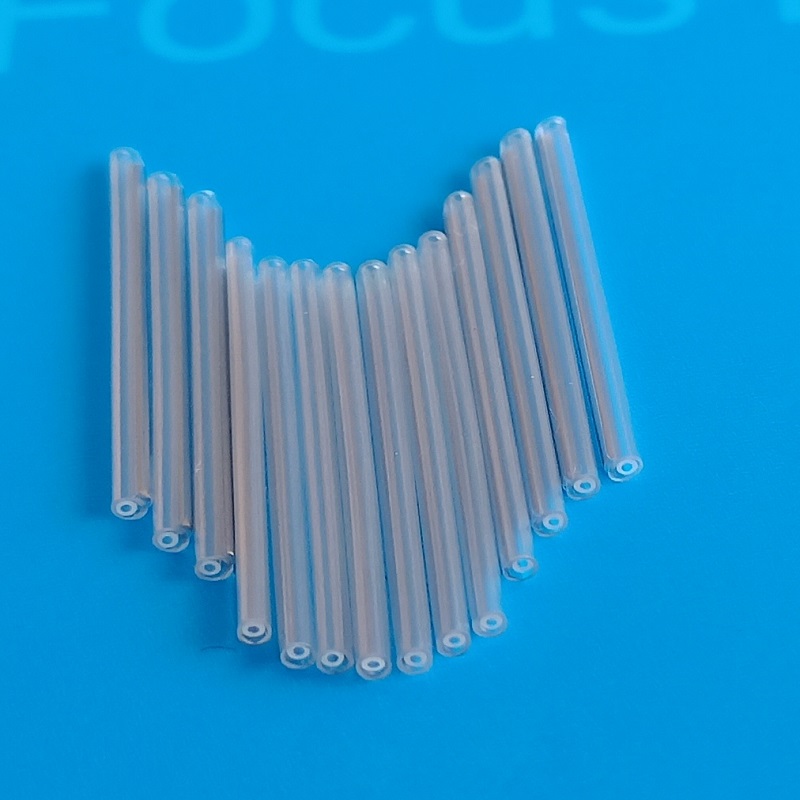

Overview:

Micro Fiber Splice Sleeves are designed for use with micro cables, which are smaller in diameter and are often used in dense, high-capacity fiber optic systems. These sleeves are specifically engineered to protect delicate fibers within compact, space-constrained areas.

Key Features:

Small Diameter: Engineered to fit smaller-diameter micro cables typically used in high-density applications.

Tight-Fit Protection: Provides a snug fit for small fibers and offers superior protection while taking up minimal space.

Advanced Material: Made from high-quality, flexible heat-shrinkable material, often with added features like flame retardancy.

Shrink Ratio: Typically a 2:1 or 3:1 ratio, allowing for a close, tight fit around the micro cable fibers.

Applications:

High-Density Fiber Optic Systems: Ideal for use in compact environments like data centers or telecom hubs, where space is limited.

Indoor Network Applications: Commonly used in installations involving smaller cables, like microcables, to ensure a secure splice in tight spaces.

Dense Wavelength Division Multiplexing (DWDM): Perfect for systems requiring high-density and high-capacity fiber connections.

Why Choose This Model:

Micro Fiber Splice Sleeves are ideal for cutting-edge, high-density fiber optic applications, offering efficient protection without occupying much space. Chengdu Focus Infra Materials company's micro fiber splice sleeves with different length, special designed for 250um micro fiber protective.

4. Ribbon Fiber Splice Sleeves

Overview:

Ribbon Fiber Splice Sleeves are designed for ribbon fiber cables, which consist of multiple fibers arranged in a flat configuration. These splice sleeves are ideal for protecting multi-fiber splices in high-density fiber optic systems.

Key Features:

Multi-Fiber Splice: These sleeves can accommodate up to 12 fibers or more, offering a multi-fiber splice solution for ribbon cables.

Large Shrink Ratio: Typically features a 3:1 or 4:1 shrink ratio to accommodate larger, multi-fiber splices.

High Strength and Durability: Made from durable, heat-shrinkable materials to provide mechanical protection, as well as resistance to environmental factors.

Protection for Multiple Fibers: These sleeves offer high-performance protection for spliced fibers in ribbon cables, ensuring minimal signal loss and high integrity.

Applications:

Ribbon Fiber Networks: Used extensively in high-density fiber optic networks, such as in long-haul telecom and backbone networks.

Data Centers: Often deployed in data center environments for organizing and protecting large-scale fiber connections.

Fiber Optic Splicing in Dense Installations: Perfect for multi-fiber splicing, ensuring minimal footprint and maximum efficiency in high-density applications.

Why Choose This Model:

Ribbon Fiber Splice Sleeves are a must-have for high-density, multi-fiber splicing applications. They are ideal for those looking to splice large numbers of fibers in a single, organized sleeve for efficient management. Chengdu Focus Infra Materials company offers ribbon fiber splice sleeves with ceramic rod and quartz rod option for your choice.

| Summary of Differences and Applications | ||

| Splice Sleeve Type | Features | Primary Applications |

| Single Fiber Splice Sleeves | Compact, durable, and versatile for single fibers. | Telecom networks, data centers, and field installations. |

| Drop Cable Fiber Splice Sleeves | Larger diameter, extra durability, and rugged design. | Fiber-to-the-Home (FTTH), outdoor fiber networks, last-mile installations. |

| Micro Fiber Splice Sleeves | Small diameter, compact design, high-density fit. | High-density fiber systems, indoor networks, data centers. |

| Ribbon Fiber Splice Sleeves | Multi-fiber splice, high shrink ratio, efficient design. | Ribbon fiber networks, data centers, long-haul telecom networks. |

Why Choose Chengdu Focus Infra Materials Company?

At Chengdu Focus Infra Materials Company, we prioritize quality, durability, and innovation in every product. Our fiber splice sleeves are rigorously tested to ensure superior performance in all types of fiber optic systems. By choosing our products, you gain the following benefits:

Unmatched Quality: Our splice sleeves are manufactured using the highest quality materials for superior performance.

Customization: We offer tailored solutions to meet the specific requirements of your fiber optic systems.

Expert Support: Our knowledgeable team is available to assist you with choosing the right product for your needs.

For more information on our range of fiber splice sleeves or to place an order, please visit our website or contact our customer service team.

RELATED NEWS

- Fiber Optic Attenuators – Precision Solutions for Signal Control 2023-03-20

- LC Fiber Optic Adapter: High-Quality Connectivity Solutions by Chengdu Focus Inf 2023-02-18

- SC Fiber Optic Adapter: High-Performance Connectivity Solutions by Chengdu Focus 2023-01-15

- Key Features of Fiber Optic Adapters 2023-04-05

- Difference Between Simplex and Duplex Fiber Optic Adapters 2023-02-22

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Yuki

Phone: +8618981876882

E-mail: yuki.hecy@cdfocusinfra.com

Whatsapp:+8618981876882

Add: No. 1760 century avenue, Chongzhou city, Sichuan province, China