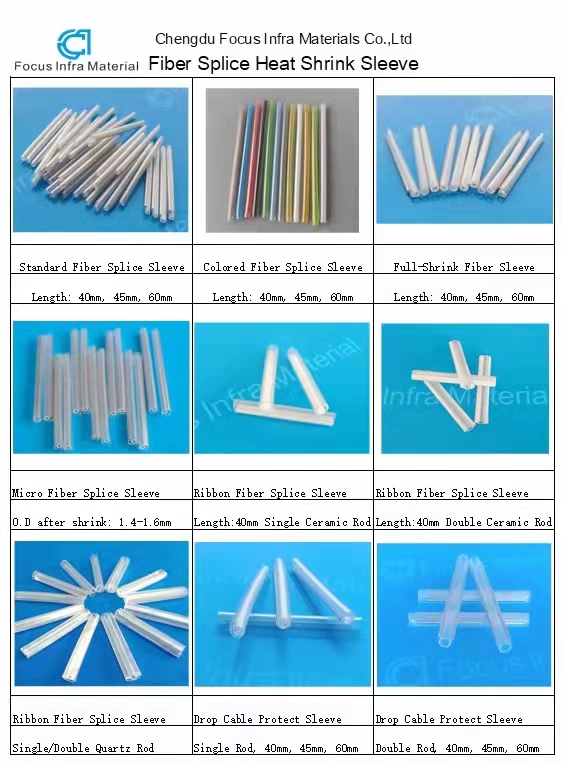

Fiber Optic Heat Shrinkable Protection Sleeves with 304SS 45mm Length for FTTH Network

Size: 1.2*45mm

Color: Transfer

Application:Fiber Fusion Protection

Package: 100pcs/bag, 24pcs/bag, customize packed

Daily Capacity: 500000pcs

Fiber Optic Heat Shrinkable Protection Sleeves with 304SS 45mm Length for FTTH Network

Description:

Fiber Optic Splice Sleeve was developed to protect and strengthen fusion splices on fiber optic cables. The Fiber Optic Splice Sleeve intends to protect (mechanically) fiber optic splices. The Fiber Optic Splice Sleeve is built from shrinkable plastic tube with metal cylinder inside. The fibers are inserted before splicing into the plastic tube. After making the splice, the shrinkable tube is heated and shrunk on the splice. It can protect the spliced fiber from being break down and unwanted bending and is coated with the plastic tube. It gives to the installer flexibility while using the spliced fibers during installation.

The Fiber Optic Splice Sleeve is fitted to the sleeve holders that are generally exist in fiber optic trays.

Product advantages:

1. Specially designed by the cross-linked polyolefin, hot melt tube and enhanced stainless steel wire optical fiber splice protection devices, does not affect the fiber optic light guide features.

2. Bare fiber hot melt, stainless steel needle, protect fiber

3. Industrial sealing treatment at both ends of the tube to keep the steel needle from falling out

4. Selected 304 high-quality stainless steel, not easy to rust, corrosion-resistant, and anti-aging

5. The double-layer shell is made of environmentally friendly PE and has a long service life

6. Better protection of bare fiber and prolong the service life of fiber

Technical Parameters:

Specification | Test method | Typical data |

Tensile strength(MPa) | ASTM D 2671 | 18 |

Elongation at Break (%) | ASTM D 2671 | 700 |

Density(g/cm2) | ISO R1183D | 0.94 |

Dielectric strength (KV/mm) | IEC 243 | 20 |

Permittivity | IEC 243 | 2.5 |

Length rate of change (%) | ASTM D 2671 | +5 |

CATEGORIES

- Fiber Optic Splice Sleeves

- Fiber Optic Adapter

- Fiber Optic Patch Cord

- Fiber Optic Fast Connectors

- Fiber Optic Cable

- Fiber Optic Splice Closures

- Cable Protection Materials

- Fiber Optic Termination Boxes

- Fiber Optic Distribution Boxes

- Fiber Optic Cable Protection Box

- FTTH Integrated Wiring Accessori

- Fiber Optical Tools

LATEST NEWS

CONTACT US

Contact: Yuki

Phone: +8618981876882

E-mail: yuki.hecy@cdfocusinfra.com

Whatsapp:+8618981876882

Add: No. 1760 century avenue, Chongzhou city, Sichuan province, China