45mm Heat Shrink Fiber Optic Splice Sleeves for FTTH Network Projects Fiber Joint Protection Sleeves

Size: 45mm

Color: Transfer

Diameter: 1.5mm

Diameter of steel rod: 0.5mm

Application:Fiber Fusion Protection

suitable for: CWDM, DWDM, Fiber telecom network

Daily Capacity: 500000pcs

45mm Heat Shrink Fiber Optic Splice Sleeves for FTTH Network Projects Fiber Joint Protection Sleeves

Description:

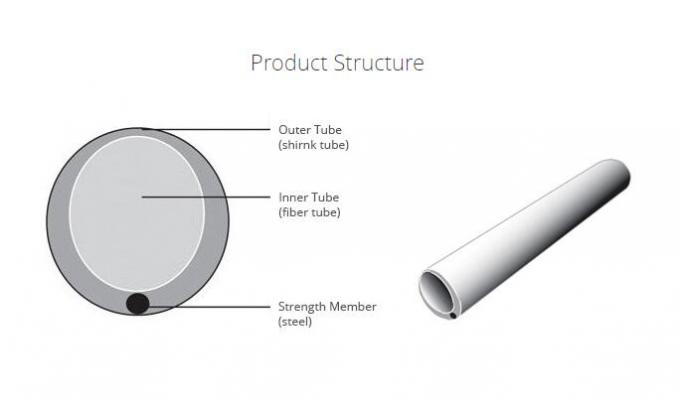

Fiber Heat Shrink Sleeve is used to protect the optical fusion fiber. Fiber Heat Shrink Sleeve provide mechanical and environmental protection for fusion splices of fiber. Fiber Heat Shrink Sleeve is compatible with most of the industry standard fiber management systems and organizers. After shrinking, it can maintain the transmission characteristics of the optical fiber, provide strength and protection to the optical joint, improve the mechanical strength of the optical fiber fusion splice, protect the splice, and ensure the reliability of the splicing.

1.4mm Small Size Mini Fiber Protection for 250μm Bare Fiber Heat Shrink Sleeve is designed for 250μm bare fiber splicing protection. Length is 45mm, 40mm, 35mm, 30mm, 25mm are available. it is special used in smaller application, such as CWDM, DWDM ect. 1.4mm Small Size Mini Fiber Protection for 250μm Bare Fiber Heat Shrink Sleeve is commonly known as an optical fiber heat shrink protect sleeve. 1.4mm Small Size Mini Fiber Protection for 250μm Bare Fiber Heat Shrink Sleeve is widely used in communication optical fiber splicing projects, it is consisted of a special cross-linked polyolefin, a hot melt tube and a strengthen member.

Features:

1. Bare fiber hot melt, stainless steel needle, protect fiber

2. Industrial sealing treatment at both ends of the tube to ensure that the steel needle does not fall

3. Selected 304 high-quality stainless steel, not easy to rust, corrosion-resistant, and anti-aging

4. Easily use and avoid any damages to the optical fiber during installation

5. Single holed (preshrunk) ends eliminates improper fiber threading

6. Smooth, rounded-end stainless steel reinforcing member ends decrease the risk of fiber damage during installation

7. Extended liner length prevents contact between the fiber and the backbone

8. Protect connection point, improve the mechanical strength, it is most reliable way to protect the fusion

Technical Parameters:

Specification | Test method | Typical data |

Tensile strength(MPa) | ASTM D 2671 | 18 |

Elongation at Break (%) | ASTM D 2671 | 700 |

Density(g/cm2) | ISO R1183D | 0.94 |

Dielectric strength (KV/mm) | IEC 243 | 20 |

Permittivity | IEC 243 | 2.5 |

Length rate of change (%) | ASTM D 2671 | +5 |

CATEGORIES

- Fiber Optic Patch Cord

- Fiber Optic Adapter

- Fiber Optic Fast Connectors

- SFP Module & Transceiver

- Fiber Optic Splice Sleeves

- Fiber Optic Splice Closures

- Fiber Optic Distribution Boxes

- Fiber Optic Termination Boxes

- Cable Protection Materials

- Fiber Optic Cable

- Fiber Optic Cable Protection Box

- FTTH Integrated Wiring Accessori

- Fiber Optical Tools

LATEST NEWS

CONTACT US

Contact: Yuki

Phone: +8618981876882

E-mail: yuki.hecy@cdfocusinfra.com

Whatsapp:+8618981876882

Add: No. 1760 century avenue, Chongzhou city, Sichuan province, China